1. Increased volume ratio;

2. Higher warehouse-in/out efficiency than manual forklift;

3. Manual remote control, realizing semi-automatic warehouse in/out;

4. Out-of-stock mode: First in first out/first in last out;

Pallet size: L1200XW1000XH1150; weight: 1000kg/pallet

Cargo space: 36 rows x 19 columns x 6 levels

Total storage: 4104 pallets

Floor area of rack: 47m long X23m wide x 9m high

Workshop floor area: 60m long x 26m x 11m high

Free Design ASRS System Industrial Automatic Warehouse High Density Storage Pallet Rack OEM ODM with Warehousing Equipment

€200,000.00

Free worldwide shipping

Free returns

Free worldwide shipping

Secure payments

Beschreibung des Produkts

Beschreibung des Produkts

Beschreibung des Produkts

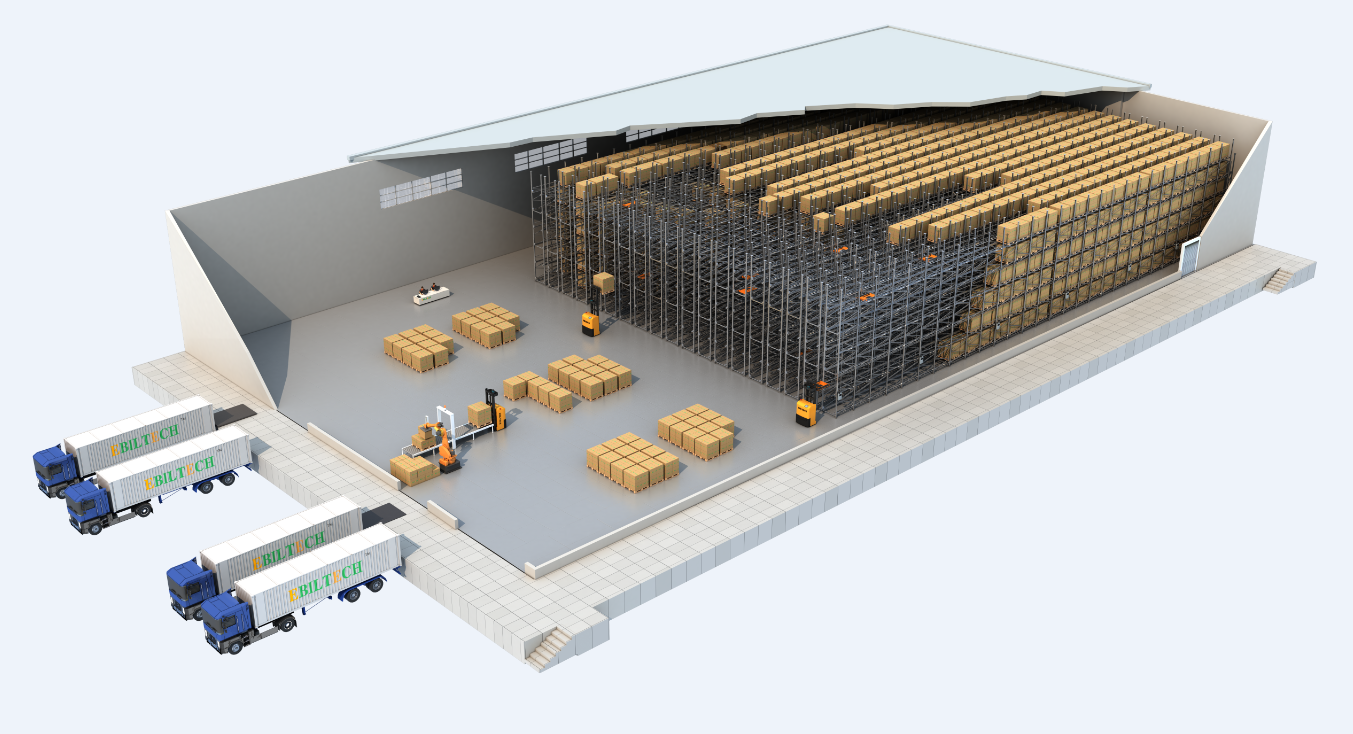

Radio shuttle racking Solution

1. Increased volume ratio;

2. Higher warehouse-in/out efficiency than manual forklift;

3. Manual remote control, realizing semi-automatic warehouse in/out;

4. Out-of-stock mode: First in first out/first in last out;

Pallet size: L1200XW1000XH1150; weight: 1000kg/pallet

Cargo space: 36 rows x 19 columns x 6 levels

Total storage: 4104 pallets

Floor area of rack: 47m long X23m wide x 9m high

Workshop floor area: 60m long x 26m x 11m high

2. Higher warehouse-in/out efficiency than manual forklift;

3. Manual remote control, realizing semi-automatic warehouse in/out;

4. Out-of-stock mode: First in first out/first in last out;

Pallet size: L1200XW1000XH1150; weight: 1000kg/pallet

Cargo space: 36 rows x 19 columns x 6 levels

Total storage: 4104 pallets

Floor area of rack: 47m long X23m wide x 9m high

Workshop floor area: 60m long x 26m x 11m high

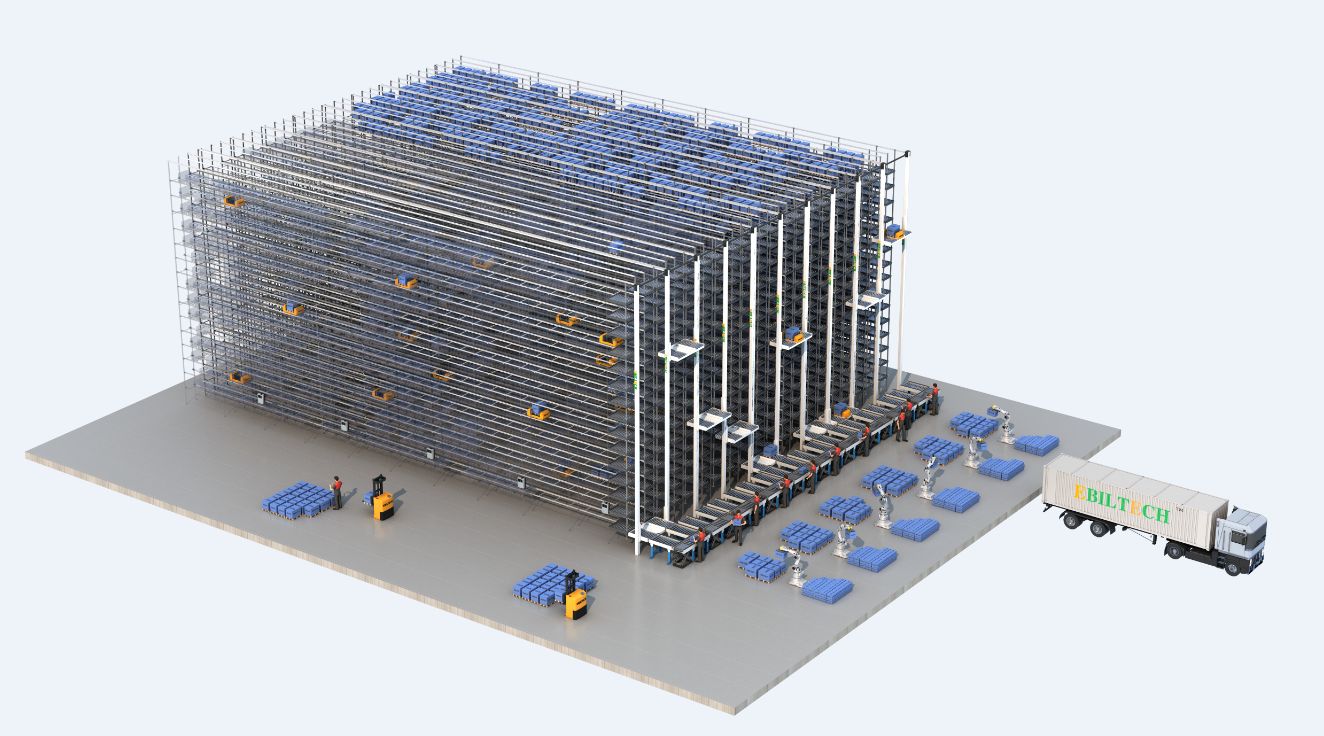

Stacker Crane + Pallet Runner System

Pallet size: L1200XW1200XH1000; weight: 1000kg/pallet

Cargo space: 22 rows x 31 columns x 9 levels

Total storage: 6138 pallets

Floor area of rack: 43.5m long X 30m wide x 13m high

Workshop floor area: 58.5m long x 38m wide x 14m high.

Cargo space: 22 rows x 31 columns x 9 levels

Total storage: 6138 pallets

Floor area of rack: 43.5m long X 30m wide x 13m high

Workshop floor area: 58.5m long x 38m wide x 14m high.

Multi shuttle System Solution

Box size: L600XW400XH280; weight: 35kg/box

Cargo space: 29 rows x 19 columns x 15 levels

Total Storage: 16530 boxes

Floor area of rack: 30m long X14m wide x 10m high

Workshop floor area: 40m long x 26m wide x 12m high.

Cargo space: 29 rows x 19 columns x 15 levels

Total Storage: 16530 boxes

Floor area of rack: 30m long X14m wide x 10m high

Workshop floor area: 40m long x 26m wide x 12m high.

Four-way Shuttle system solution

——Line side library of smart factory workshop.

——Frozen/fresh food warehouse

——Logistics transition center.

——Unmanned dark warehouse.

——Line side library of smart factory workshop.

——Frozen/fresh food warehouse

——Logistics transition center.

——Unmanned dark warehouse.

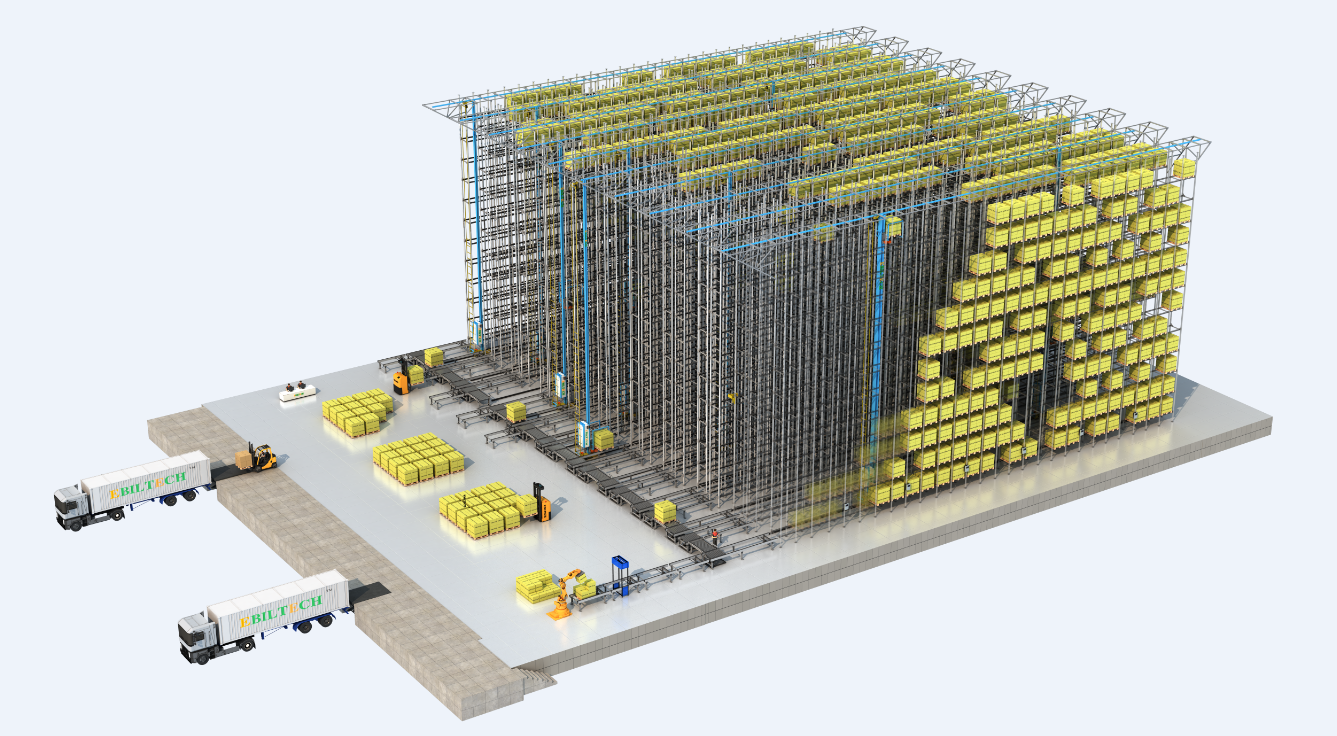

Staker Crane System

Pallet size: L1200XW1200XH1200;

Weight: 1000kg/pallet

Cargo space: 27 rows x 20 columns x 12 levels

Total storage: 6480 pallets

Floor area of rack: 43m long X 45m wide x 19m high

Workshop floor area: 65m long x 55m wide x 20m high

Weight: 1000kg/pallet

Cargo space: 27 rows x 20 columns x 12 levels

Total storage: 6480 pallets

Floor area of rack: 43m long X 45m wide x 19m high

Workshop floor area: 65m long x 55m wide x 20m high

Primary-secondary Shuttle carrier solution

Pallet size: L1200XW1200XH1000; weight: 1000kg/pallet

Cargo space: 22 rows x 31 columns x 9 levels

Total storage: 6138 pallets

Floor area of rack: 43.5m long X 30m wide x 13m high

Workshop floor area: 58.5m long x 38m wide x 14m high.

Cargo space: 22 rows x 31 columns x 9 levels

Total storage: 6138 pallets

Floor area of rack: 43.5m long X 30m wide x 13m high

Workshop floor area: 58.5m long x 38m wide x 14m high.

Title goes here.

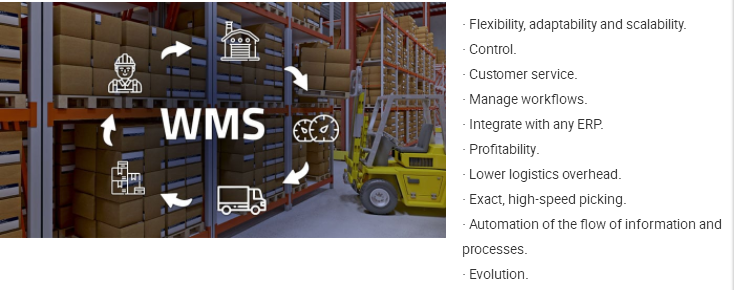

The Warehouse Control System (WCS) serves as a bridge between the Warehouse Management System (WMS) and a broad range of material handling equipment such as conveyor systems, automated storage and retrieval systems, carousels, sorters, palletizers and so on.

Acting as a “hub”, the WCS is responsible for keeping everything running smoothly and maximizing the efficiency of material

handling systems and subsystems.

Acting as a “hub”, the WCS is responsible for keeping everything running smoothly and maximizing the efficiency of material

handling systems and subsystems.

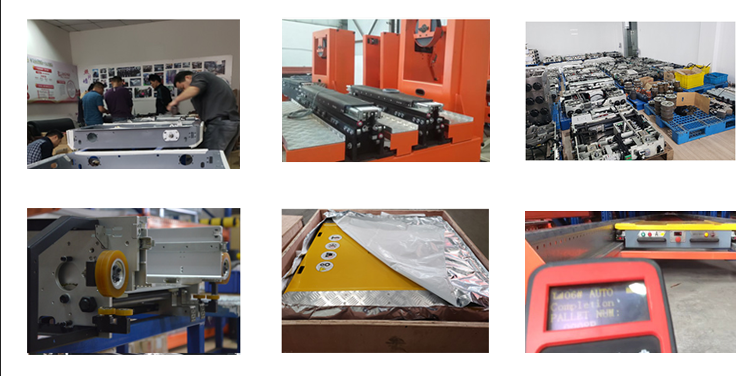

1.Q: Are you distributor or manufacturer?

A: We are professional and leading manufacturer for nearly 20 years.We produce and export high quality pallet racking ,Multi shuttle system and Rodio shuttle racking,ASRS which have a very high reputation among our customers. Our anual production capacity is 100,000 tons of rack components and 1,000 units of shuttle cars.

A: We are professional and leading manufacturer for nearly 20 years.We produce and export high quality pallet racking ,Multi shuttle system and Rodio shuttle racking,ASRS which have a very high reputation among our customers. Our anual production capacity is 100,000 tons of rack components and 1,000 units of shuttle cars.

2.Q: What makes you different with others?

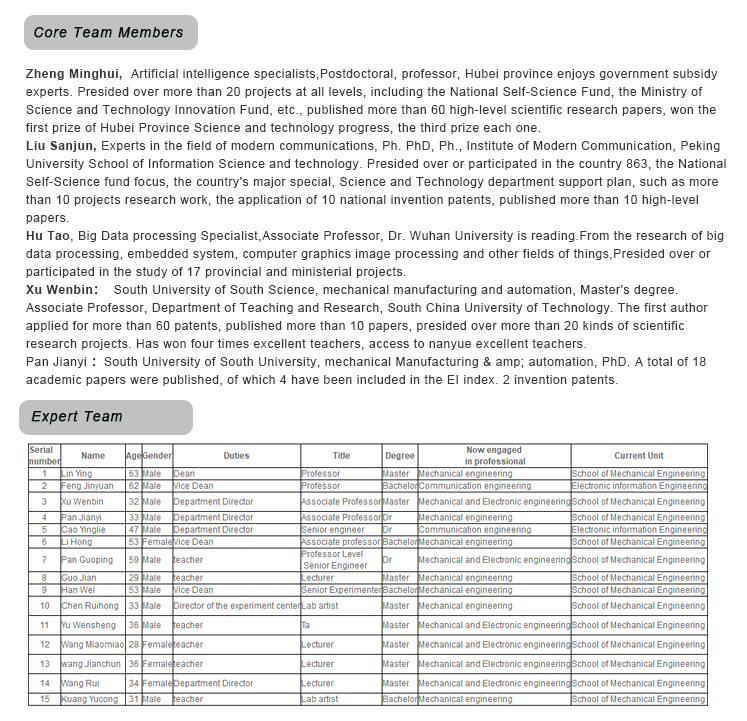

A: 1) We have more than 40 mechanical, electrical and software engineers. EBILTECH always attaches great importance to product innovation and R&D. It not only has its own research and development team, but also cooperates with domestic well-known research institutes, so as to continuously enhance the technical strength of the enterprise.Our independent research and development of WMS system and WCS system.We have more than 60 national patents.

2)Our Excellent Service

For a quick, no hassle quote just send email to us

We promise to reply with a price within 24 hours - sometimes even within the hour.

If you need an advice, just call our export office at 0086-25-52757208, we will answer your questions immediately.

3)Our quick manufacturing time

For Normal orders, we will promise to produce within 20-30 days.

As a manufactoiy, we can essure the delivery time according to the formal contract.

3.Q: What is the installation and debugging services?

A: We have installation teams with rich overseas experience. For radio shuttle car, we will send engineers to the site for

debugging and training. For racking systems, we can installate by our own teams or appoint engineers to guide the operation.We have done many project in southease Asia,American, European.

4. Q:What is the MOQ can order?

A:Normally is one 20ft container, but large quantity comes with good price

5.Q: What is the payment?

A: T/T or LC

2)Our Excellent Service

For a quick, no hassle quote just send email to us

We promise to reply with a price within 24 hours - sometimes even within the hour.

If you need an advice, just call our export office at 0086-25-52757208, we will answer your questions immediately.

3)Our quick manufacturing time

For Normal orders, we will promise to produce within 20-30 days.

As a manufactoiy, we can essure the delivery time according to the formal contract.

3.Q: What is the installation and debugging services?

A: We have installation teams with rich overseas experience. For radio shuttle car, we will send engineers to the site for

debugging and training. For racking systems, we can installate by our own teams or appoint engineers to guide the operation.We have done many project in southease Asia,American, European.

4. Q:What is the MOQ can order?

A:Normally is one 20ft container, but large quantity comes with good price

5.Q: What is the payment?

A: T/T or LC

zuletzt angesehen